Kaleidoscopic Laser Alignment Calibration: 2025’s Tech Revolution & Billion-Dollar Forecasts Unveiled

Table of Contents

- Executive Summary: 2025 Industry Overview & Key Insights

- Market Size & Growth Forecasts Through 2030

- Breakthrough Technology Innovations in Laser Alignment Calibration

- Key Players and Strategic Partnerships (2025 Edition)

- Emerging Applications: From Aerospace to Micromanufacturing

- Regulatory Frameworks and Industry Standards

- Competitive Landscape: OEMs, Disruptors, and New Entrants

- Supply Chain & Component Advancements

- Investment Trends and Funding Outlook (2025–2030)

- Future Outlook: Challenges, Opportunities & Predictions for the Next 5 Years

- Sources & References

Executive Summary: 2025 Industry Overview & Key Insights

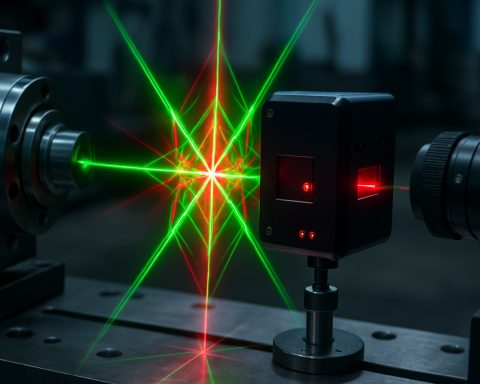

Kaleidoscopic laser alignment calibration is emerging as a transformative technique in the precision engineering and optics industries, offering unparalleled accuracy for the alignment of optical systems, semiconductor equipment, and advanced manufacturing lines. As of 2025, the sector is experiencing robust expansion, fueled by rising demand for high-precision instrumentation in sectors such as photonics, microelectronics, and medical devices. The technology leverages the unique properties of kaleidoscopic optics to generate complex, multi-beam laser patterns, enabling simultaneous multi-axis alignment and reducing setup times compared to traditional single-beam methods.

Current industry leaders, including Newport Corporation and Thorlabs, Inc., have introduced next-generation kaleidoscopic laser alignment systems with enhanced spatial resolution, automated feedback loops, and adaptive calibration algorithms. These innovations are addressing the increasing miniaturization of components and the stringent tolerances demanded by next-generation photonic and quantum computing devices. Notably, Carl Zeiss AG has expanded its offerings in the optical metrology space to incorporate kaleidoscopic calibration modules, which are now being deployed in both R&D and production environments to boost throughput and reduce error rates.

Recent deployments in semiconductor fabrication facilities have demonstrated a measurable reduction in alignment error margins—often by more than 30%—and a corresponding increase in process yields. For instance, collaborations between optics suppliers and microchip manufacturers, such as those between Coherent Corp. and leading foundries, are driving the adoption of kaleidoscopic laser alignment in wafer steppers and mask aligners. Real-world data from these deployments indicate downtime reductions of up to 20%, as well as improved repeatability in large-scale production runs.

Looking ahead, the outlook for kaleidoscopic laser alignment calibration remains highly positive. Industry roadmaps suggest ongoing integration with AI-driven control systems, enabling self-optimizing alignment routines and predictive maintenance. Companies like Hamamatsu Photonics K.K. are investing in smart sensor modules that will further automate calibration, making the technology accessible to a broader range of users beyond large-scale manufacturers. As these capabilities mature, the market is expected to see accelerated adoption across medical imaging, aerospace, and precision manufacturing sectors over the next few years.

Market Size & Growth Forecasts Through 2030

The market for kaleidoscopic laser alignment calibration systems is entering a dynamic growth phase in 2025, propelled by rapid advances in photonics, manufacturing automation, and precision metrology. This technology, which leverages multi-faceted optical elements and laser sources to achieve ultra-precise alignment across complex geometries, is increasingly vital for industries such as semiconductor fabrication, aerospace, advanced optics, and medical device manufacturing.

Recent investments and product launches underscore the sector’s momentum. Carl Zeiss AG and KEYENCE CORPORATION have both introduced enhanced laser alignment modules in the past year, targeting high-throughput environments where nanometer-level accuracy is essential. These launches coincide with growing adoption of Industry 4.0 principles, where real-time calibration and digital integration are becoming standard requirements on factory floors globally.

In 2025, the demand for kaleidoscopic laser alignment calibration is particularly robust in semiconductor equipment manufacturing and precision optics, with both sectors expanding their capital expenditure on high-precision metrology solutions. For example, ASML Holding N.V., a leader in photolithography systems, continues to increase its alignment and calibration capabilities to support next-generation chip production, reflecting similar trends across the supply chain.

Looking ahead to 2030, the market outlook remains bullish. Factors driving sustained growth include the miniaturization of electronic components, proliferation of advanced driver-assistance systems (ADAS) in automotive manufacturing, and expansion of additive manufacturing processes—all of which demand rigorous alignment and calibration. Companies such as HORIBA, Ltd. and Hexagon AB are expanding their product portfolios to serve these evolving requirements, investing in R&D for faster, more automated, and AI-integrated calibration solutions.

By the end of this decade, analysts anticipate that kaleidoscopic laser alignment calibration systems will be integral to smart factories and digital twins, with cloud-based analytics and remote diagnostics further enhancing value propositions. Strategic partnerships between equipment manufacturers, integrators, and end users—such as those recently announced by Leica Geosystems AG—are expected to accelerate deployment and drive double-digit annual growth rates through 2030, especially in Asia-Pacific and North America.

Breakthrough Technology Innovations in Laser Alignment Calibration

Kaleidoscopic Laser Alignment Calibration represents a cutting-edge evolution in the precision calibration landscape, leveraging complex beam-splitting optics and real-time multidirectional feedback systems. The core innovation is the use of kaleidoscopic or multifaceted optical assemblies to split and redirect coherent laser beams, enabling simultaneous, high-resolution measurement of alignment parameters across multiple axes. This technology is especially transformative for industries where ultra-fine alignment is critical, such as advanced semiconductor manufacturing, photonics assembly, and high-precision robotics.

In 2025, leading manufacturers are integrating kaleidoscopic calibration modules into production metrology systems, driven by the need for increased throughput and sub-micron accuracy. Renishaw, a prominent metrology solutions provider, has announced the development of multi-beam laser interferometry platforms, which use advanced beam-splitting optics for simultaneous multi-axis measurement, reducing calibration time significantly. Similarly, Zygo Corporation has introduced interferometric systems equipped with complex optical arrangements for multi-dimensional alignment verification, targeting semiconductor wafer steppers and mask aligners.

Emerging data from pilot installations in 2024 and 2025 indicates that kaleidoscopic laser calibration can improve alignment accuracy by up to 35% compared to conventional single-beam systems, while reducing system calibration cycles by nearly half. These gains are particularly evident in precision motion platforms and coordinate measuring machines (CMMs), where even minute misalignments can propagate significant errors across production lines.

Industry standards bodies are also responding to these innovations. The American Society of Mechanical Engineers (ASME) is reviewing updates to its B5.54 performance standards to accommodate multi-beam and kaleidoscopic calibration methodologies, reflecting the technology’s growing adoption in mission-critical manufacturing. Furthermore, automation system integrators such as FANUC are piloting the use of kaleidoscopic laser modules in robotic calibration cells, aiming to support next-generation assembly lines for electric vehicles and microelectronics.

Looking ahead, the outlook for kaleidoscopic laser alignment calibration is robust. Anticipated improvements in beam-splitting materials and digital signal processing—propelled by collaboration between optics specialists and semiconductor equipment manufacturers—are expected to further enhance accuracy and speed. As the technology matures, it is poised to become the gold standard for multi-axis alignment, enabling smarter, faster, and more reliable manufacturing in the years immediately beyond 2025.

Key Players and Strategic Partnerships (2025 Edition)

The landscape of kaleidoscopic laser alignment calibration in 2025 is marked by intensified innovation and a surge in strategic collaborations among industry leaders, optics manufacturers, and automation solution providers. The sector is evolving rapidly to meet the rising demands of precision manufacturing, semiconductor processing, and advanced robotics—all of which require meticulous alignment solutions bolstered by laser-based technologies.

A standout player in this space is Thorlabs, which continues to expand its portfolio of laser alignment and calibration tools. In 2025, Thorlabs has deepened its collaborations with semiconductor equipment manufacturers to integrate its kaleidoscopic alignment modules into automated wafer inspection systems, aiming to bolster sub-micron accuracy and throughput in chip fabrication lines.

Meanwhile, Newport Corporation is leveraging its Opto-Electronics division’s expertise to launch modular kaleidoscopic laser calibration kits suited for both research laboratories and industrial production lines. Newport’s recent partnership with leading robotics integrators highlights a trend towards embedding laser calibration in next-generation autonomous assembly cells, enabling real-time correction and adaptive alignment to minimize downtime and maximize yield.

European optics powerhouse Carl Zeiss AG has also announced a strategic alliance in 2025 with several precision engineering firms to co-develop AI-enhanced calibration systems. These systems combine kaleidoscopic laser arrays with machine learning algorithms to self-diagnose alignment drift and initiate automated recalibration, responding to the needs of the fast-growing medical device manufacturing sector.

In Asia, Keyence Corporation is pushing the boundaries of high-speed, multi-axis alignment calibration. Their 2025 product launches focus on compact, plug-and-play kaleidoscopic laser units tailored for electronics assembly and display panel inspection, with strategic supply agreements now in place with major consumer electronics brands.

Looking ahead, the sector is likely to witness even closer integration between hardware suppliers and software developers. The proliferation of Industry 4.0 initiatives is fostering collaborations that bring together companies like Leica Geosystems—renowned for its spatial laser measurement systems—and cloud analytics providers, enabling real-time global calibration monitoring and predictive maintenance.

Collectively, these alliances and innovations are poised to set new benchmarks in the kaleidoscopic laser alignment calibration market, ensuring robust, traceable, and adaptive solutions for the precision industries of tomorrow.

Emerging Applications: From Aerospace to Micromanufacturing

Kaleidoscopic laser alignment calibration—using advanced optics to split and align multiple laser beams with high precision—has seen accelerating adoption across a spectrum of industries, notably aerospace and micromanufacturing, as of 2025. These systems enable dynamic, real-time calibration of sophisticated optical assemblies, supporting the growing complexity and miniaturization of modern technologies.

In aerospace, the demand for sub-millimeter accuracy in component assembly and quality assurance has driven the integration of kaleidoscopic laser alignment systems into both manufacturing and maintenance workflows. For instance, Lockheed Martin has incorporated multi-beam laser alignment for precise assembly of satellite optical payloads and reflective surfaces, reducing error margins and manual rework. Similarly, Airbus utilizes laser-based calibration platforms for alignment of critical avionics and sensor arrays, reporting improved throughput and reduced calibration cycle times.

Within micromanufacturing, the trend toward miniaturized electronics and microelectromechanical systems (MEMS) has placed a premium on non-contact, ultra-high accuracy alignment. Companies like TRIOPTICS have launched kaleidoscopic laser calibration modules that can align optical fibers and micro-lenses with nanometer precision, enabling automated production lines for advanced photonics and wearable devices. Their systems are now being adopted by leading semiconductor fabs to improve yield in photolithography and wafer inspection processes.

Emerging applications are also seen in the medical device sector, where laser calibration provides the accuracy needed for assembling micro-catheters and surgical instruments. Carl Zeiss AG has developed modular alignment solutions using kaleidoscopic laser arrays, specifically tailored for high-throughput inspection and assembly of micro-optics in diagnostic equipment.

- In 2025, automated alignment calibration is expanding beyond prototyping into full-scale production, fueled by AI-driven feedback and closed-loop control systems.

- Collaborative projects between aerospace OEMs and laser system suppliers are underway to standardize alignment protocols for next-generation satellites and aircraft sensors.

- Micromanufacturing leaders are deploying integrated kaleidoscopic laser calibration to support the transition to chiplet and 3D packaging technologies.

Looking ahead, the next few years are expected to bring increased levels of integration between kaleidoscopic laser calibration systems and industrial robotics, as well as the emergence of in-situ calibration platforms for additive manufacturing and quantum device fabrication. This will further enhance precision and productivity across sectors where alignment tolerances are measured in nanometers.

Regulatory Frameworks and Industry Standards

The regulatory landscape for kaleidoscopic laser alignment calibration is rapidly evolving in response to the increasing integration of advanced laser-based systems across industries such as semiconductor manufacturing, automotive, and precision optics. As of 2025, global standards organizations and national regulatory bodies are addressing the unique challenges posed by the complexity and precision required in kaleidoscopic laser alignment.

Key international bodies, notably the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), are updating and expanding their standards for laser safety (ISO 11553 series) and alignment calibration protocols. These standards are being harmonized with the latest technological advancements in multi-beam and kaleidoscopic laser systems, emphasizing traceability, reproducibility, and environmental safety.

In the United States, the Occupational Safety and Health Administration (OSHA) and Food and Drug Administration (FDA) continue to oversee compliance with performance standards for laser products, including those used in high-precision alignment. The FDA’s Center for Devices and Radiological Health is expected to release updated guidance in 2025 to address emerging technologies in kaleidoscopic laser alignment, focusing on operator safety and product labeling requirements. In addition, the Laser Institute of America (LIA) is actively contributing to the development of best practices and certification programs tailored to the demands of multi-beam alignment systems.

Within the European Union, the European Commission is aligning directives such as the Machinery Directive (2006/42/EC) and the Low Voltage Directive (2014/35/EU) with new EN standards for laser calibration, responding to the growing adoption of kaleidoscopic alignment equipment in industrial automation and healthcare. The VDE Association for Electrical, Electronic & Information Technologies and national standardization bodies are collaborating to ensure harmonized implementation and mutual recognition of certifications.

Looking ahead, industry leaders such as Carl Zeiss AG and Hexagon AB are engaging with standards bodies to provide technical input for next-generation calibration protocols, ensuring that future frameworks are robust enough to support innovations in adaptive and AI-driven alignment systems. The next few years will likely see the release of specialized standards for kaleidoscopic laser calibration, with an emphasis on interoperability, real-time verification, and integration with digital quality management systems.

Competitive Landscape: OEMs, Disruptors, and New Entrants

The competitive landscape for kaleidoscopic laser alignment calibration is characterized by rapid technological innovation, convergence of established optical metrology OEMs, and the emergence of agile disruptors leveraging photonics miniaturization and AI-driven calibration. As of 2025, global players in precision alignment—particularly those with roots in semiconductor, biomedical, and advanced manufacturing—are integrating kaleidoscopic methodologies to achieve multi-axis, high-throughput calibration unattainable with conventional techniques.

Among established OEMs, Carl Zeiss AG and Keyence Corporation are notable for advancing laser alignment solutions incorporating prism-based beam splitting and dynamic pattern generation, essential features of kaleidoscopic calibration. Carl Zeiss AG has expanded its Industrial Metrology portfolio in 2024–2025 to support real-time, in-line calibration of robotics and semiconductor lithography, while Keyence Corporation has integrated multi-spot and multi-wavelength laser modules into their latest alignment systems for electronics and medical device assembly.

In the optics and photonics sector, Thorlabs, Inc. and Edmund Optics have introduced modular kaleidoscopic beam delivery kits aimed at research and OEM integration, targeting both laboratory and industrial automation customers. These platforms support rapid prototyping and custom calibration routines, which has helped lower entry barriers for startups and research consortia seeking to implement kaleidoscopic alignment at scale.

Disruptors are harnessing computational imaging and AI-driven feedback to push beyond hardware-centric calibration. TRIOPTICS GmbH has developed closed-loop kaleidoscopic alignment systems with real-time machine vision, enabling dynamic compensation of misalignments in precision optics assembly. Meanwhile, startups such as Laser Components GmbH (noted for their custom photonic modules) have begun collaborating with automation integrators to embed kaleidoscopic calibration into next-generation production lines across Europe and North America.

Looking ahead, the next few years are expected to see intensified collaboration between traditional OEMs, photonics startups, and industrial automation platforms. Industry consortia are driving interoperability standards for kaleidoscopic alignment modules, and several OEMs are actively piloting cloud-based calibration analytics platforms. As AI integration matures, competitive differentiation will increasingly hinge on software ecosystems, intelligent feedback loops, and the ability to adapt to diverse manufacturing and inspection environments.

Supply Chain & Component Advancements

The supply chain and component ecosystem for kaleidoscopic laser alignment calibration is undergoing rapid transformation in 2025, driven by demand from advanced manufacturing, semiconductor, and precision optics sectors. This calibration methodology, which leverages multi-angle laser arrays and sophisticated detection to enhance alignment accuracy, is increasingly dependent on new materials, miniaturized photonics, and integration-ready subsystems.

Major component suppliers are improving the stability and reliability of optical mounts and beam-splitter arrays, essential for the kaleidoscopic approach. Companies like Thorlabs, Inc. have expanded their offerings in high-precision kinematic mirror mounts and optomechanical assemblies, directly addressing the needs of multi-beam alignment systems. Simultaneously, Edmund Optics is releasing new grades of anti-reflective coated optics and low-thermal-expansion substrates, which are critical for maintaining calibration fidelity across variable operational environments.

Laser diode manufacturers are innovating with compact, wavelength-stabilized, and polarization-maintaining sources to meet the strict requirements of kaleidoscopic systems. For example, Coherent Corp. and Lumentum Holdings Inc. are scaling up production of narrow-linewidth laser modules designed for interferometry and precision alignment tasks. This is crucial as industries such as lithography and flat panel display assembly demand alignment tolerances at the nanometer scale.

On the detection side, advancements in position-sensitive detectors (PSD) and high-speed cameras are streamlining feedback loops in real-time calibration. Hamamatsu Photonics K.K. continues to push the envelope on dynamic range and spatial resolution for sensor arrays used in alignment monitoring. Moreover, integration with programmable automation controllers is becoming standard, with NI (National Instruments) providing modular data acquisition and signal processing solutions tailored to multi-beam calibration setups.

Supply chain resilience is a growing focus, as the sector seeks to mitigate risks from geopolitical tensions and raw material shortages. Firms are increasingly dual-sourcing critical components and investing in domestic manufacturing capabilities. Additionally, cross-industry partnerships between optical component makers and robotics integrators are accelerating the deployment of turn-key kaleidoscopic alignment platforms, reducing lead times for end users in precision assembly and inspection lines.

Looking ahead to 2026 and beyond, the trend is toward further miniaturization, greater automation, and increased integration of AI-driven error correction in calibration workflows. With substantial investments from leading suppliers and a robust pipeline of enabling technologies, the supply chain for kaleidoscopic laser alignment calibration is poised for continued expansion and sophistication.

Investment Trends and Funding Outlook (2025–2030)

The investment landscape for kaleidoscopic laser alignment calibration technologies is poised for significant growth in 2025 and the following years, driven by expanding applications across precision optics, semiconductor manufacturing, and advanced photonics. As manufacturing tolerances tighten and demand for highly accurate, real-time alignment solutions rises, both established corporations and venture-backed startups are intensifying their focus on innovation within this niche sector.

Leading industry players such as Carl Zeiss AG and Keyence Corporation have recently announced increased R&D budgets aimed at enhancing laser-based alignment systems, with a particular emphasis on integrating kaleidoscopic multi-beam projection for real-time calibration in high-throughput environments. TRIOPTICS GmbH, a specialist in optical measurement and manufacturing equipment, has also unveiled plans for expanding its portfolio of automated laser calibration modules, reflecting the sector’s growing commercial momentum.

In terms of capital inflows, the sector is attracting both strategic investments and public-private partnerships. The European Union’s Quantum Technologies Flagship initiative continues to allocate funding to photonics and laser alignment projects, supporting startups and academic-industry consortia working on scalable calibration solutions. In the United States, National Science Foundation grants and Department of Energy programs are earmarking resources for advanced laser metrology, further catalyzing research commercialization.

Startups specializing in AI-driven alignment calibration—for example, those working with adaptive optics and real-time feedback algorithms—are also attracting venture capital. Partnerships between innovation accelerators such as imec and semiconductor manufacturers are expected to intensify, aiming to bridge laboratory advances with on-the-fly calibration requirements in chip fabrication.

Looking ahead to 2030, the outlook for investment remains robust, underpinned by the ongoing miniaturization of optical systems and the proliferation of autonomous manufacturing. Industry analysts anticipate a surge in acquisitions and collaborative R&D agreements, especially as companies seek to secure intellectual property and integration capabilities for next-generation laser alignment systems. The sector’s trajectory suggests that kaleidoscopic laser alignment calibration will be a focal point for both technological evolution and investor interest throughout the latter half of this decade.

Future Outlook: Challenges, Opportunities & Predictions for the Next 5 Years

The landscape for kaleidoscopic laser alignment calibration is set to evolve rapidly through 2025 and the following years, driven by increasing demand for high-precision optical systems in fields such as semiconductor manufacturing, photonics research, and advanced imaging. As applications in quantum computing, autonomous vehicles, and medical diagnostics demand ever tighter tolerances, the calibration of complex, multi-path laser systems—often involving kaleidoscopic or multi-beam arrangements—has become both a technical challenge and a market opportunity.

A significant challenge remains the automation of alignment and calibration procedures. Manual or semi-automated methods, though still widespread, are increasingly a bottleneck as system complexity rises. Companies such as Newport Corporation and Thorlabs, Inc. are actively developing integrated solutions that combine precision actuators, interferometric sensors, and real-time feedback algorithms to minimize human intervention. These systems are expected to reduce calibration time and improve repeatability, a critical factor as production scales up for photonics chips and next-generation displays.

Another opportunity arises from advances in metrology devices capable of analyzing multiple laser paths simultaneously. Recent innovations from Zygo Corporation and Keysight Technologies leverage high-speed, multi-channel interferometry and machine vision, allowing for the rapid detection and correction of misalignments in kaleidoscopic laser setups. Such capabilities are particularly relevant for wafer inspection and lithography systems, where sub-nanometer accuracy is mandatory.

Integration with artificial intelligence is also forecast to accelerate. Several sector leaders are investing in AI-driven calibration routines that can learn from prior alignment cycles and anticipate error patterns, further reducing downtime and enhancing system robustness. This is underscored by ongoing collaborations between Hamamatsu Photonics and academic research consortia focusing on adaptive optics.

Looking ahead, the next five years are likely to see increased standardization efforts led by industry groups such as the SEMI association, which aims to harmonize calibration protocols across equipment vendors. This will facilitate interoperability, reduce integration costs, and accelerate adoption in emerging sectors such as quantum information science and advanced LIDAR systems.

In summary, while challenges persist in automating and standardizing kaleidoscopic laser alignment calibration, rapid technological advances, cross-sector collaboration, and AI integration point to a future where these procedures become faster, more reliable, and essential to the deployment of next-generation photonics technologies.

Sources & References

- Thorlabs, Inc.

- Carl Zeiss AG

- Coherent Corp.

- Hamamatsu Photonics K.K.

- ASML Holding N.V.

- HORIBA, Ltd.

- Hexagon AB

- Renishaw

- American Society of Mechanical Engineers (ASME)

- FANUC

- Lockheed Martin

- Airbus

- TRIOPTICS

- International Organization for Standardization (ISO)

- European Commission

- VDE Association for Electrical, Electronic & Information Technologies

- Laser Components GmbH

- Lumentum Holdings Inc.

- NI (National Instruments)

- Quantum Technologies Flagship

- National Science Foundation

- imec